The core competence of VIDEOTON BULGARIAN HOLDINGS Ltd. is providing low to high volume and high mix assembly of subassemblies and final products: Household Appliances, Electrical subassemblies and devices.

This core activity is made even more integrated and competitive by a strong local part manufacturing with the support of VT Bulplast Ltd.

In-house Injection Molding of thermoplastic parts and Compression & Injection Molding of thermoset materials precede electromechanical assembly of the products. They are manufactured on assembly stations and lines developed and installed by our highly qualified engineers.

- Low & Medium & High Volume complex assembly lines;

- Continuous flow production lines with 100% in-line functional testing;

- Complete visual inspection of parts;

- Material tracking and work in progress processes.

VTBH capabilities include electro-mechanical and box-build assembly by skilled and trained personnel.

We strive to offer flexible operation and customized services through the right balance of experience, equipment, technologies, staff and training to meet the needs of our customers.

We master strong Production management and full Supply Chain Management expertise. Supported by MRP system, we ensure full control from production planning and purchasing materials throughout the complete production cycle.

Our employees' competence and Quality System assure error-free assembly processes. Engineering and management teams continually control quality processes to maintain the highest levels of performance.

Processes:

- Coil winding & Cutting & Forming

- Ultrasonic & Spot Welding

- Soldering

- Threading, Stripping

- Clamping, Crimping

- Manual & Semi-Automatic Assembly

- Tampon Printing,

- Pressing, Riveting

- Wrapping

- Shrinking, Taping, Gluing

- Magnetic & Thermal & Resistance & High-voltage & Functional Testing

Our strategy:

- Resource optimization and efficient performance, project follow-up

- Short-term project implementation

- Continuous development of our technology base

- Human resource development

- Higher competitiveness

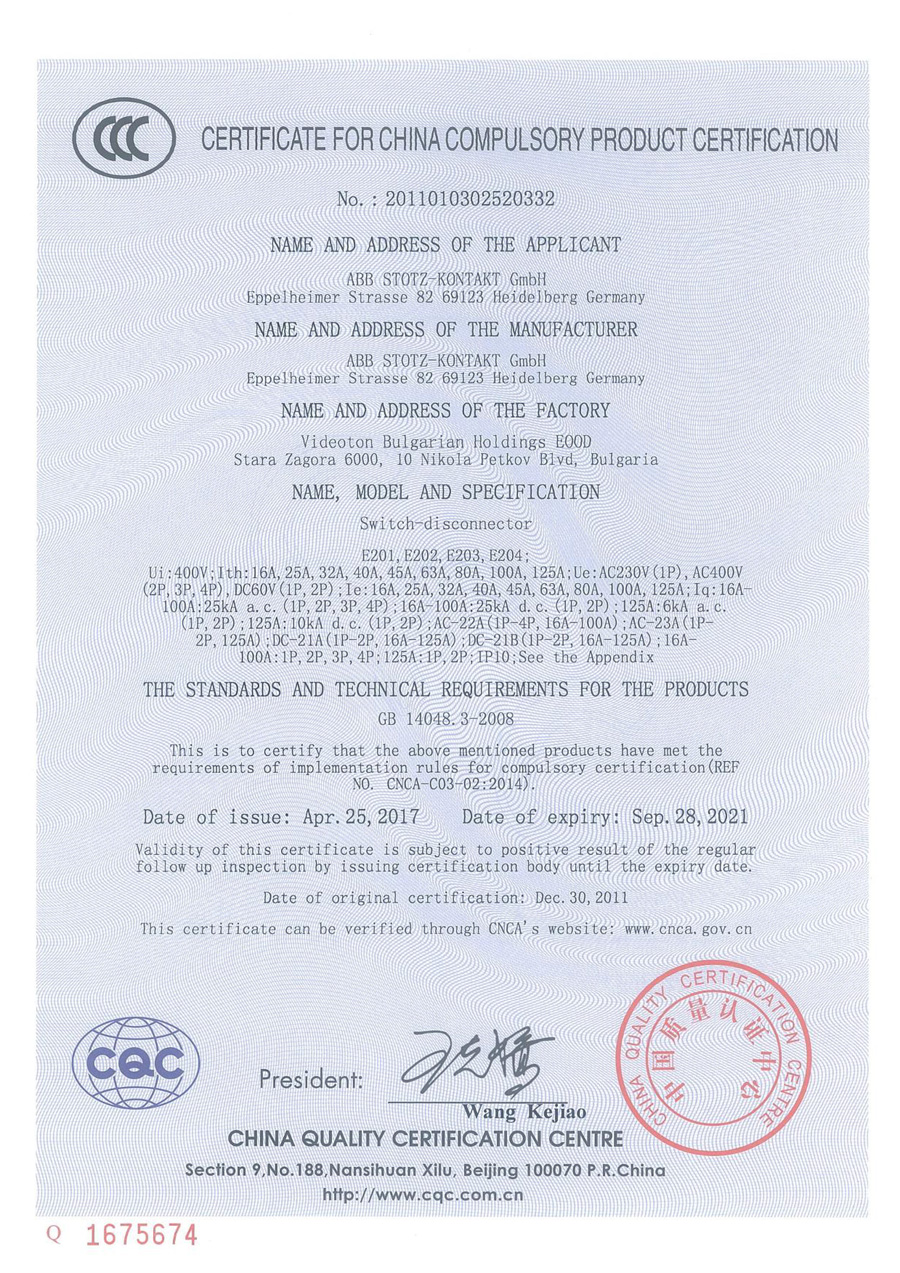

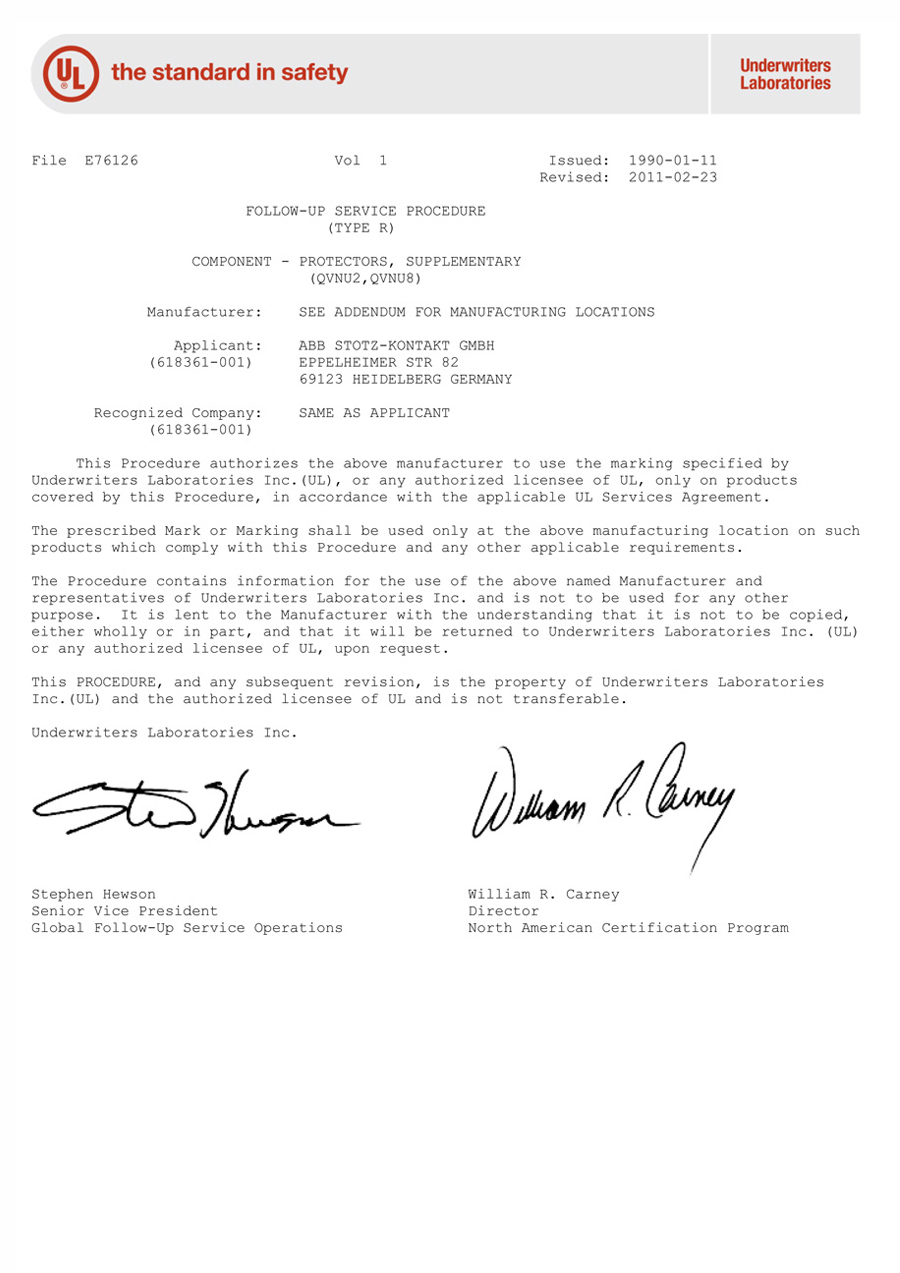

Products Certifications

- UL Product Certification

- CSA Certificate

- VDE Certificate

- KEMA-KEUR certification mark certified by DEKRA

- CCC Certificates for China Compulsory Product Certification

- Our Customers: ABB, SCHNEIDER, LEGRAND, ELECTROLUX, SENSUS, ELERO, PHILIPS

Our philosophy of project management is to get to know our customers well, their objectives, priorities and delivery needs. Then, apply the full resources of the company to each project, to meet or exceed customer's expectations.

The project management teams are led by dedicated Project Managers who work closely with personnel from all business units. We create dedicated cross-functional inter-company teams, made up of representatives from Materials management, Engineering, Manufacturing, Maintenance, Quality and Sales departments. This group stays with a project from concept design to distribution, becoming an extension of our customer's own staff, providing customers with full support, problem solving and leadership at every phase of a project.

Management of Transfer Projects

- Best class references in diverse transfer projects

- Competent team to prepare and accomplish the complete relocation with / without customer’s interactive participation

- Competent staff with more than fifteen years’ experience in transferring over fifty projects from world-wide known partners establishing efficient cooperation

- High flexibility in business set-up

- Available industrial properties: production & logistics facilities, offices

- Full range of Industrial park services

- Vast experience in wide range of processes, customer - specific ones included

Product Management incl. NPI capabilities

We pay a particular focus on new product design projects, in which we are involved in early stage as co-developing partners of our customers. Our creative engineering team is able to accomplish industrialisation of new products through a wide range of design and engineering services, including development of the processes, hardware and software design.

Production

- Create Project planning detailing all stages of industrialization

- Develop assembly lines & manufacturing processes, Process flow-chart

- Risk analysis: development of PFMEA

- Develop and manufacture specific production tooling, jigs and other special purpose equipment

- Software design

- Offer competent solutions for quality improvement, cost & process optimization

- Technical change management

- Support in any technical issues related to production processes and/or equipment

- Regular maintenance of production equipment

Test

- Develop test processes

- Develop and manufacture test equipment & fixtures

- Software design

- Regular maintenance & calibration of test equipment & tooling